Quality control

Quality control is the main key to readymade garments. It ensures product value & customer satisfaction. It also leads to brand reputation. However, most people need to learn the actual definition of quality control. They want to limit quality control to checking procedures only. Q.C is not only limited to finished garments. Still, it is practiced in the garment industry from the initial stage of procurement of raw materials to the stage of final garment production. Q. control in garment manufacturing is the process of determining inspection requirements, inspecting products, finding defects, and making repairs or corrections. Q- control is specific order criteria such as design, size, quality, and dress accessories. In this article, we are going to know the best way to do QC activities in the readymade garment industry. Also visit

How to initiate quality control activities:

If some one ask, what is the quality? Anyone can easily say the quality is a standard, So will the standard be the same for everyone? Of course not; it is a man variable. Quality is the customer’s demand. That’s why, first, Set your goal for what you will do. Make a structural analysis of the selected items, like fabric & raw materials. When you find out what you have to do, why does it do it? Then, you can set how to do it, and that’s the proactive approach. When setting goals or benchmarks, you can implement a quality control plan.

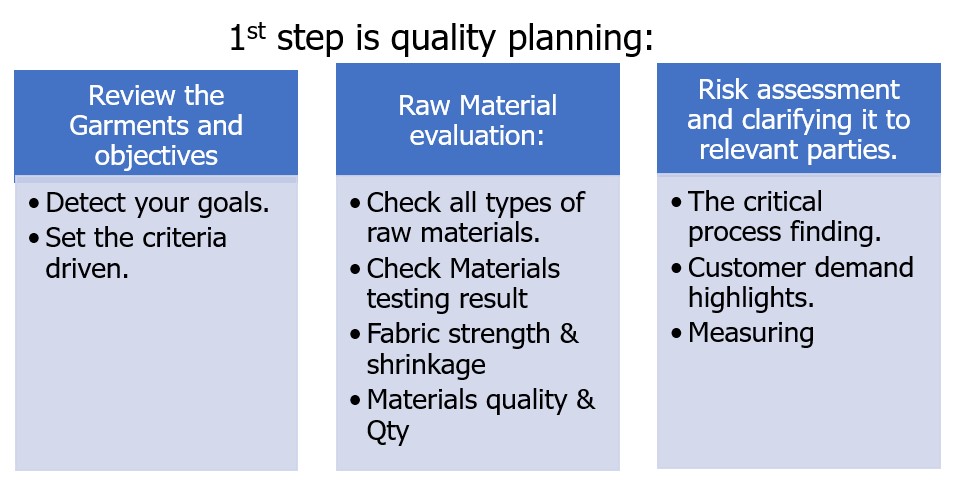

Q. Planing

- Review the Garments and objectives

- Detect your goals.

- Set the criteria driven.

- Raw Material evaluation

- Check all types of raw materials.

- Check Materials testing result.

- Fabric strength & shrinkage.

- Materials quality & qty.

- Risk assessment and clarifying it to relevant parties.

- The critical process finding.

- Customer demand highlights.

- Measuring.

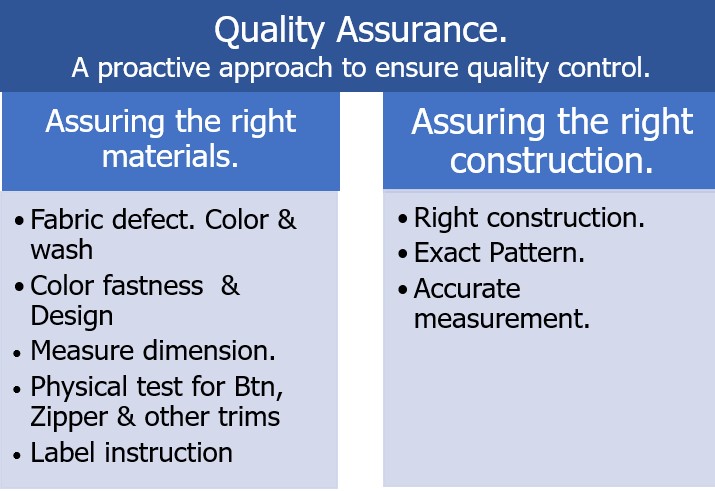

Quality Assurance.

- Assuring the right materials.

- Fabric defect. Color & wash

- Color Fastness & Design

- Measure dimension.

- Physical test for Btn, Zipper & other trims

- Assuring the construction.

- Assure the sewing construction.

- Exact pattern.

- Accurate measurement.

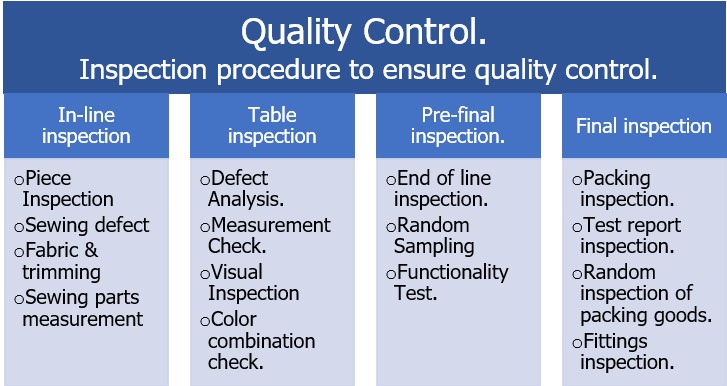

Quality Control.

Inspection procedure to ensure quality control.

Inspection, about quality management in the apparel industry, can be defined as the visual examination or review of raw materials (such as fabric, buttons, zippers, sewing thread, trim, etc.), partially finished components of the garment, and as a whole. This level of q- control is called the Quality Control Team.

- In-line inspection

- Piece Inspection

- Sewing defect

- Fabric & trimming

- Sewing parts measurement

- Table inspection

- Defect Analysis.

- Measurement Check.

- Visual Inspection

- Colour combination check.

- Pre-final inspection.

- End-of-line inspection.

- Random Sampling

- Functionality Test.

- Final inspection

- Packing inspection.

- Test report inspection.

- Random inspection of packing goods.

- Fittings inspection.

Conclusion:

This way, you can easily ensure quality control in the garment industry. Remember to first know the customer’s needs. Products that meet standards and customer expectations are quality. A simple but effective way to implement quality control is to establish standardized inspection points at each stage of production. This may include checks during fabric cutting, sewing, finishing, and packaging. Using clear quality guidelines for each stage ensures consistency.

Another method is the random checking system, where a small percentage of each batch of garments is thoroughly inspected for problems such as loose threads, incorrect stitching, or sizing. Training staff on quality standards and encouraging accountability are essential to ensure that errors are not overlooked. We have to remember that we will not make bad quality garments & we will not endorse wrong. products.

Author : Abdul Aziz

Head of sample & Innovation.

Standard Group.