Quality Control as a Profession in Apparel Industry.

Why choose Quality Control as a Profession in the Apparel Industry? Currently, the garment industry acts as the duck that lays the golden egg for Bangladesh’s economy. Therefore, to sustain this industry, we must ensure we provide quality products or services that meet customer expectations. Maintaining consistency serves as one of the key tools for long-term survival in today’s competitive market.

Several factors determine the quality of the garments produced by the garment industry. For instance, whether they will be comfortable to wear, their durability, the color retention, and their design – etc. We can easily understand that quality forms a key ingredient for the success of any business. Customers won’t spend their hard-earned money on poor-quality products. Therefore, we view quality as the product’s ability to meet the customer’s expectations.

Quality Control Definition in the Apparel Industry

A business follows a process known as quality control to monitor the quality of its products and services. This doesn’t only mean controlling, but ensuring that their products and services meet quality standards and satisfy the customer’s needs.

During the production of goods or services, the organization must adhere to certain predetermined policies, procedures, or processes when crafting their specific goods or services, ensuring they align with international standards. Therefore, the organization must foster a working environment where everyone concentrates on perfecting their work to improve quality. Regular training, establishing a benchmark to measure product or service quality, and checking for significant variations in the produced products or services are essential elements of this process.

Quality Control History.

The father of QC is DR. Joseph M. Juran who passed away on February 28, 2008. He was 103 years old at the time of his death. He was born in Braila, Romania in 1904.

Dr. Juran has traveled the world teaching people how to improve quality. He founded the Juran Institute in 1979 when he was 85 years old. Many of his works are still acclaimed worldwide. For example, Six Sigma tools are still used around the world to improve business efficiency.

He has done a lot of work on quality control and management. The first standard reference on quality management is written by his hand. Besides, the book he wrote called Quality Control Handbook was first published in 1951. It is currently in its 6th edition.

Quality Control why take it your profession?

Quality of essential products which we assume to be very safe. We simply trust the brand or label of the product and use it. The quality control team increased this trust to a hundred percent. Quality control in garment manufacturing is not only for customer satisfaction. But also aids in improving productivity and efficiency. Hence, quality control plays a crucial role in reducing production costs and achieving customer satisfaction. Since there is a wide range of options, you have the opportunity to work in this profession. The salary structure ranges from 12-15 thousand, and one can earn around 90 thousand to 1 lakh 20 thousand with 5-7 years of experience. What is quality control? How you can set up as a quality controller in a garments factory. What is required to be a quality controller and where you can study?? I will discuss this in detail about the topic.

Quality Control skills and where to work in the apparel industry?

To work in quality control at national and international standards, you must acquire the following skills.

- Must have a proper understanding of fabrics and yarns.

- Must know the manufacturing process of the readymade garment industry.

- Ability to work with heterogeneous data and knowledge of various quality control methods.

- Good communication skills, which will be useful when working with customers and employees. Ability to handle stress with patience

- Able to handle team work.

If you take quality control as a profession, you will get job opportunities in various organizations involved in the garment industry.

- Buying House

- Spinning mill

- Fabrication mill

- Dyeing mill

- knitting mill

There is an opportunity to work in the washing unit of products including the ready-made garments industry.

Quality control where you can study?

Short courses, diploma, and graduation – you can take training on garment quality at various levels.

Bangladesh University of Textile Engineering (BUTEX) is the most famous educational institute of textile engineering in Bangladesh. Graduate degrees are awarded from Jhenaidah, Noakhali, Pabna, Chittagong, and Barisal Textile Engineering Colleges under this institution. Apart from this, among the public universities, there is an opportunity to study textile engineering at Khulna University of Engineering and Technology (KUET), Dhaka University of Engineering and Technology (DUET), Maulana Bhasani University of Science and Technology.

Textile engineering can also be studied in a total of 13 private universities in Bangladesh including Ahsanullah University of Science and Technology (AUST), BJMEA University of Fashion and Technology, and Daffodil International University.

Quality Control career and salary in the apparel industry?

As a Quality Control Officer, one can become a Quality Control Manager within 5 – 9 years depending on the organization. If you work efficiently and if you are skilled in office management and executive work, it is possible to work at the executive level of the company.

The starting salary as a quality control executive is a monthly salary of TK15,000 – TK25,000. After one and a half to two years, the salary increases to TK25,000 – Tk40,000 per month on promotion to senior executive. The monthly salary of the Quality Control Manager ranges from 50 thousand to 1 lakh 20 thousand. A monthly salary of one and a half to two lakh taka is given in large companies.

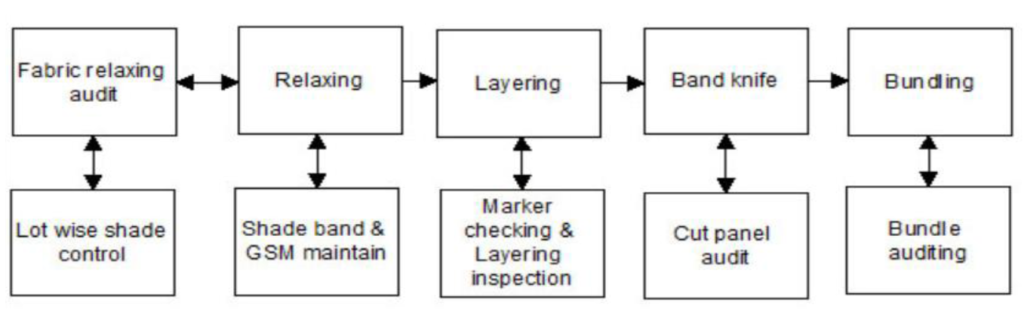

Steps of Quality Control in the apparel industry.

The first method of quality control is to first know the structure of the quality control. Apparel manufacturing usually consists of Man, Machine, Materials, Method, and Money. Therefore, depending on this, the quality test criteria or standards are defined:

Checking the raw materials of the product and observing the various stages of the production process

Taking action to solve problems when identified

Information gathering and decision-making

Quality Control Checklist

Determination of raw material demand

Determination of packaging

Checking the quality of products by visiting the site

Categorize errors if any

Quality Control Poor Quality and Impact on Apparel Manufacturers:

Low-quality products are not acceptable to customers

A certain quantity of goods cannot be exported at a specified time

If defects are high, production will decrease

Poor quality products waste time and money to correct defects

Due to low production, timely shipment is not possible

Buyer levies penalty for supply of defective and substandard products

Providing low-quality products does not lead to customer confidence in the company.

Conclusion:

In this 21st century of globalization, markets are becoming more and more complex, and that’s why every industry is facing a high level of competition for their business. So the product must fulfill the customer’s requirement. For this reason, every product should maintain a quality level.

Quality is defined as the level of acceptance of a good or service. It is a very essential requirement for any kind of product. Every product should maintain the standard quality level and product quality is calculated in terms of the quality standard of fiber, and yarn. Fabric construction, color fastness, design, and the final finished garment.

Nowadays customers are very much quality-conscious. If it is possible to maintain a high Quality system of inspection policy, the buyers shall be motivated and more quality products can be made.

Md. Abdul Aziz

Head of Innovation

Source: Online